The research team believes the approach could revolutionise regenerative medicine, enabling the production of complex tissues and cartilage that would potentially support, repair or augment diseased or damaged areas of the body. So far, printing high-resolution living tissues is a challenge, as the cells often move within printed structures and can collapse on themselves. Led by Professor Hagan Bayley, Professor of Chemical Biology in Oxford’s Department of Chemistry, the Oxford University team devised a way to produce tissues in self-contained cells that support the structures to keep their shape.

Layer by layer assembly

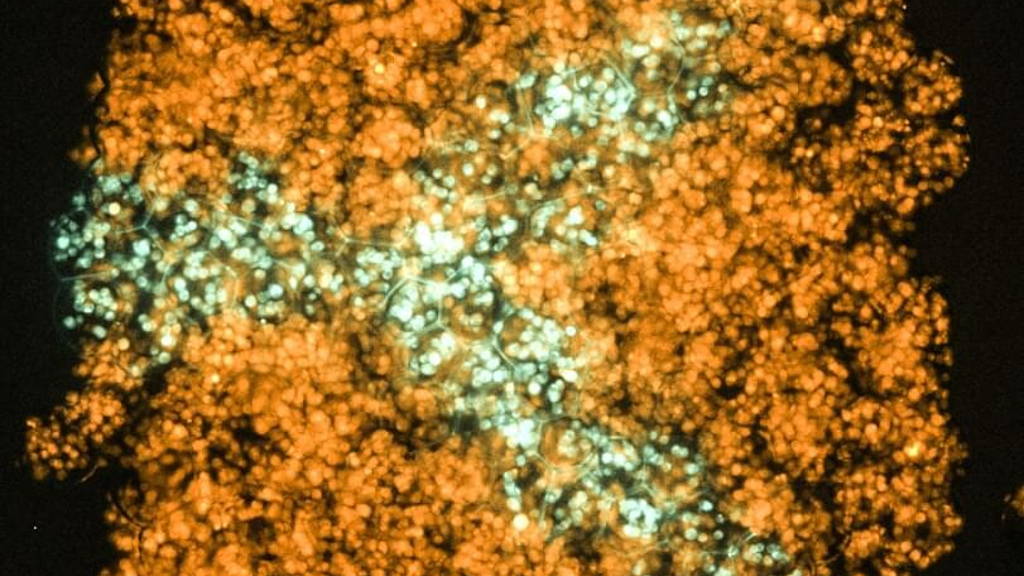

The cells were contained within protective nanolitre droplets wrapped in a lipid coating that could be assembled, layer-by-layer, into living structures. Producing printed tissues in this way improves the survival rate of the individual cells, thus allowing the team to improve on current techniques by building each tissue one drop at a time into a more favourable resolution.

To be useful, artificial tissues need to be able to mimic the behaviours and functions of the human body. The method enables the fabrication of patterned cellular constructs, which, once fully grown, mimic or potentially enhance natural tissues.

According to dr Alexander Graham, lead author and 3D Bioprinting Scientist at OxSyBio (Oxford Synthetic Biology), the team aimed at fabricating three-dimensional living tissues that could display the basic behaviours and physiology found in natural organisms.

“To date, there are limited examples of printed tissues, which have the complex cellular architecture of native tissues. Hence, we focused on designing a high-resolution cell printing platform, from relatively inexpensive components, that could be used to reproducibly produce artificial tissues with appropriate complexity from a range of cells including stem cells’.”

Shaping reproducible human tissue models

Don’t expect a quick go-to-market yet. But with further development, the materials could have a wide impact on healthcare worldwide. Potential applications include shaping reproducible human tissue models that could take away the need for clinical animal testing.

Over the coming months work will commence on the development of new complementary printing techniques, that allow the use of a wider range of living and hybrid materials, to produce tissues at industrial scale. Dr Sam Olof, Chief Technology Officer at OxSyBio, underlines the many potential applications for bioprinting, with possibilities for personalised treatments by using cells sourced from patients to mimic or enhance natural tissue function. “In the future, 3D bio-printed tissues maybe also be used for diagnostic applications – for example, for drug or toxin screening.”

Dr Adam Perriman from the University of Bristol’s School of Cellular and Molecular Medicine, added: ‘The bioprinting approach developed with Oxford University is very exciting, as the cellular constructs can be printed efficiently at extremely high resolution with very little waste. The ability to 3D print with adult stem cells and still have them differentiate was remarkable, and really shows the potential of this new methodology to impact regenerative medicine globally.’