Now, biocompatible, water-based inks containing GRMs have been developed as building blocks for ink-jet printable electronic devices, the website from the EU-project Graphene Flagship states. Importantly, the inks can be used to successfully ink-jet print electronic devices based on combinations of different layered materials, according to an article by Sophia Lloyd.

The research Lloyd writes about was published in Nature Nanotechnology and was performed in a collaboration between researchers at the University of Manchester, UK and the University of Pisa, Italy.

Ink-jet printing is a fast and accessible route to printed electronics, because of simple switching of design and materials. The devices were produced using a material ink-jet printer available in the market, demonstrating the suitability of this technique as a platform for rapid prototyping (similar to 3D printing), while paving the way towards print-on-demand electronics.

Gianluca Fiori, a researcher at the department of Information Engineering at the University of Pisa, Italy, said: “We are now entering a new scenario in the field of electronics, where electronic systems can be printed on demand and on flexible substrates as paper. GRMs based inks could indeed represent an enabling technology for the fast-growing market of flexible and portable electronics.”

The research was led by Cinzia Casiraghi, a researcher in the School of Chemistry at the University of Manchester, UK. She explained that the printable heterostructures are “the first step towards the realization of low-cost and flexible devices.”

One important area where these printed circuits could find application is in smart packaging. The Internet of Things is enabling connectivity in an unprecedented range of applications, and smart packaging could be ideal for managing inventories and monitoring spoilage in food, drinks and pharmaceuticals; applications for which the ink’s biocompatibility is essential.

With a budget of €1 billion, the project represents a new form of joint, coordinated research on an unprecedented scale, forming Europe's biggest ever research initiative. The Graphene Flagship is tasked with bringing together academic and industrial researchers to take graphene from the realm of academic laboratories into European society in the space of 10 years, to generate economic growth, new jobs and new opportunities. The core consortium consists of over 150 academic and industrial research groups in 23 countries. In addition, the project has a growing number of associated members that will be incorporated in the scientific and technological work packages from the Horizon 2020 phase (1 April 2016 – 31 March 2018).

The research Lloyd writes about was published in Nature Nanotechnology and was performed in a collaboration between researchers at the University of Manchester, UK and the University of Pisa, Italy.

Printing electronics

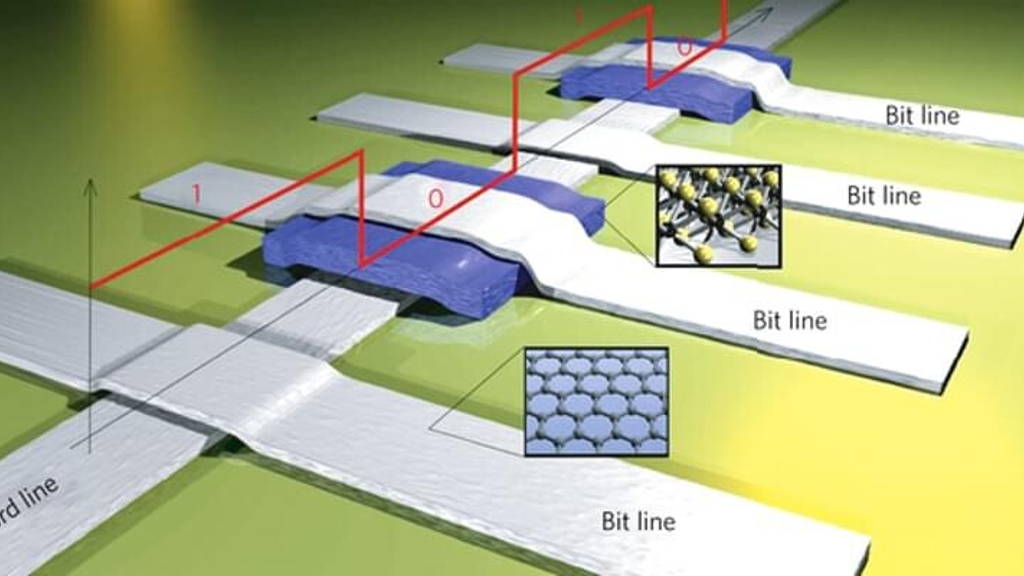

The GRM inks contain conductive graphene, the insulator hexagonal boron nitride (hBN) and semiconductor transition metal dichalcogenides (TMDs), such as MoS2 and WS2. This provides the full range of electronic properties needed to print complex electronics, including photodetectors. The inks can be printed onto flexible and stiff substrates, such as paper, glass and plastic, while the inks’ biocompatibility also suggests possibilities for printing biomedical devices such as sensor implants.Ink-jet printing is a fast and accessible route to printed electronics, because of simple switching of design and materials. The devices were produced using a material ink-jet printer available in the market, demonstrating the suitability of this technique as a platform for rapid prototyping (similar to 3D printing), while paving the way towards print-on-demand electronics.

Gianluca Fiori, a researcher at the department of Information Engineering at the University of Pisa, Italy, said: “We are now entering a new scenario in the field of electronics, where electronic systems can be printed on demand and on flexible substrates as paper. GRMs based inks could indeed represent an enabling technology for the fast-growing market of flexible and portable electronics.”

Ink formula optimized

Typically, with ink-jet printing it is very difficult to obtain good interfaces, meaning the printed devices do not operate reliably. For these new inks, the researchers optimised the ink formula specifically for ink-jet printing, adding xantham gum as a binder to prevent the printed interfaces merging together.The research was led by Cinzia Casiraghi, a researcher in the School of Chemistry at the University of Manchester, UK. She explained that the printable heterostructures are “the first step towards the realization of low-cost and flexible devices.”

One important area where these printed circuits could find application is in smart packaging. The Internet of Things is enabling connectivity in an unprecedented range of applications, and smart packaging could be ideal for managing inventories and monitoring spoilage in food, drinks and pharmaceuticals; applications for which the ink’s biocompatibility is essential.

About the Graphene Flagship

The Graphene Flagship is a Future and Emerging Technology Flagship by the European Commission.With a budget of €1 billion, the project represents a new form of joint, coordinated research on an unprecedented scale, forming Europe's biggest ever research initiative. The Graphene Flagship is tasked with bringing together academic and industrial researchers to take graphene from the realm of academic laboratories into European society in the space of 10 years, to generate economic growth, new jobs and new opportunities. The core consortium consists of over 150 academic and industrial research groups in 23 countries. In addition, the project has a growing number of associated members that will be incorporated in the scientific and technological work packages from the Horizon 2020 phase (1 April 2016 – 31 March 2018).